PV Elite

PV Elite® is pressure vessel and heat exchanger design software is easy to learn and use. PVElite® gives users fast start-up and confidence in their safety code calculations.

PV Elite® provides engineers, designers, estimators, fabricators and inspectors with solutions that match their pressure vessel and heat exchanger design needs. Because the program is easy to learn and use, it is perfect for both regular and occasional users requiring fast start up and confidence in their safety code calculations.

PV Elite is a complete solution for the quick and intuitive design of new pressure vessels, and it also evaluates and re-rates existing vessels, including Fitness for Service analysis. The program considers the whole vessel, addressing all of the wall thickness rules and stress analysis requirements for vertical towers, horizontal vessels and heat exchangers.

Key Features

- Data Collection

PV Elite makes defining pressure boundary conditions for vessels and exchangers easy.

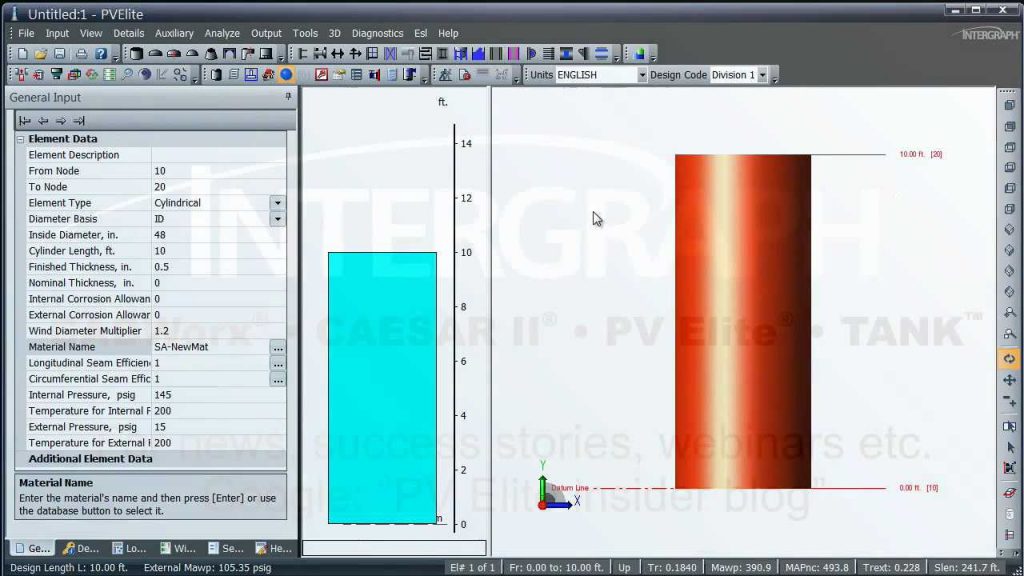

- Graphics

Graphical representation of analysis models helps ensure confidence in the input and results.

- Analysis Options

PV Elite performs calculations in accordance with ASME Section VIII Divisions 1 & 2, PD 5500, and EN 13445.

- Output and Reports

To simplify inspection requirements, PV Elite lists the most important equations, such as required thickness and MAWP.

- Materials and Codes

PV Elite is a global package with international code rules plus extensive region-specific content.

- Interfaces

PV Elite interfaces with other popular software packages for finite element analysis, foundation design, and drafting.

- PV Fabricator™

PV Fabricator offers advanced tools for the production of fabrication deliverable’s of pressure vessels and heat exchangers.

PV Elite® Industries

Chemical : Engineers in the chemical or petrochemical industry often experience a variety of challenges during the pressure vessel design verification process, including time constraints and inherent delays. With PV Elite®, you can perform verification in a quick and efficient way.

Equipment : Pressure vessel equipment manufacturers, suppliers, and designers use PVElite® to realize efficiency. From reducing design cycle times to performing quick and accurate calculations, PV Elite helps you design and engineer equipment with confidence.

Food and Beverage : The food and beverage industry has a wide variety of facilities, complete with varying demands. The approach to a brewing facility will differ greatly from a processing plant. With that in mind, there is a single software solution available when designing pressure vessels and heat exchangers

Offshore : PVElite also makes the most of the data that you put into it. Information is collected into helpful subsets and is also entered to simplify inspection requirements. Important equations, such as thickness and maximum allowable working pressure, are grouped together and summarized for easy review.

Pharmaceutical :PV Elite generates graphical analysis models complete with international code rules and specific regional content. These layers of data are easy to manipulate. Data can also be synchronized with other AutoCAD®-based solutions offered by Intergraph, CADWorx® Plant Professional and PV Fabricator®

Piping : The plant design process, engineers, designers, and other stakeholders must be able to communicate seamlessly. From creating revenue-earning deliverables to synchronizing data, CADWorx® and PV Elite® follow the philosophy of “enter once – use many times.” Entering data once for multiple purposes helps reduce the costs and time involved. Plus, it leads to greater accuracy because models are automatically updated instead of having a new model created for each task.

Power : Whether you engineer equipment for the power industries or design power plants, you’ll find a number of reasons why PV Elite® is the premier pressure vessel and heat exchanger design software.

Process Plant Design : This comprehensive pressure vessel design software solution can be used to perform load analysis calculations to ensure compliance with ASME codes as well as test the effects of wind and seismic conditions.Entering data in PV Elite is intuitive and reliable. In fact, it has helped plant designers and engineers reduce inaccuracies and expedite the heat exchanger and pressure vessel design process.

Shipbuilding : PV Elite helps you examine conditions specific to a marine environment. From providing regional wind and seismic content to ensuring models comply with international vessel codes, PV Elite delivers even under the most extreme uses.

Water Treatment : The pressure vessel and heat exchanger design process for water treatment facilities. Heat exchangers help maintain temperatures and assist with the pollutant removal process. No matter the heat exchanger you wish to design.